Windshields don’t crack on your agenda. They crack on a single-digit morning if you happen to rush to defrost, or underneath a summer time solar that turns your cabin right into a kiln. Rock chips are small, but temperature turns them cruel. The resin treatments otherwise. Glass contracts or expands simply sufficient to show a tiny megastar spoil into a walking crack. If you're employed in automobile glass fix otherwise you with no trouble care approximately your auto, the legislation difference whilst the thermometer swings to both excessive. I’ve repaired chips at minus 15 and at 110 in the shade. The ways aren't the related, and the margin for mistakes shrinks.

This assist gets into the gritty certainty of windshield chip restoration when it’s too bloodless or too hot for comfort. Expect lifelike settings, field-tested workarounds, and the industry-offs no one mentions on these smooth equipment packing containers.

Why temperature shakes the rules

Glass is a inflexible, amorphous forged. It expands and contracts with warm, about nine × 10^-6 in keeping with level Celsius. That determine appears tiny unless you spread it across a windshield measured in toes, then upload localized heat from a defroster vent or a sunbeam pinning the upper nook. Now introduce a rock chip with microfractures radiating from an impact cone. Those fractures widen and narrow as temperature shifts, which changes how resin flows, bonds, and cures.

Resin doesn’t play pleasant either. Low temperatures growth viscosity. High temperatures speed up curing and shorten working time. UV intensifies the reaction, so iciness solar close the mountains can nevertheless medication speedy once you’re now not observing, and a summer cloud can rob you of consistency.

What topics in follow: manage. When the weather is going severe, you'll need keep an eye on glass temperature, resin conduct, and UV publicity satisfactory to stabilize a truly small, very subtle house of spoil.

Understanding chip anatomy earlier than you start

Not each chip should still be treated the equal approach, enormously in harsh temperatures. A easy bullseye with a good seal behaves another way than a star smash with lengthy legs. A mixture wreck with overwhelmed effect point will vent another way than a shallow part-moon. The more vents and micro-cracks you have got, the greater they reply to thermal tension. Translation: that superstar destroy on a five-degree morning is primed to run the instant you apply pressure or warm.

Two short truth checks I make earlier than any rock chip restore while it’s 20 or a hundred tiers outside:

- If a leg has already reached the brink of the glass, it's no longer a chip restoration process. It’s windshield crack restore territory, and area cracks are notoriously delicate to temperature. Replace or enhance accordingly. If illness is apparent, like moisture or washing machine fluid frozen inside the destroy, you desire greater time and a warmness source to dry it competently. Injecting resin into a rainy or icy hollow space will entice illness and cloud the restore.

Cold weather: less than forty F, the principles tighten

The hardest bloodless paintings I’ve finished concerned regular wind, unmarried-digit temps, and a truck parked nose-first into the breeze. In that environment, each step counts. The best chilly possibility is a run: a leg that suddenly extends since you pressured strain on chilly, shrunk glass.

Warm the glass, not simply the air around it. Aim for a tumbler temperature among 60 and eighty F in the restore area. Use an infrared thermometer, not your hand. Hands lie. Glass beneath 50 F acts obdurate. Resin crawls, bubbles remain, and UV takes longer than you suspect.

Take care with warm. Too a whole lot warm in one spot can twist the glass layers and start a crack. I pick a small warmth gun on low or a devoted glass hotter with a diffuser, saved shifting, not at all closer than 6 to eight inches. Spend three to five mins bringing the neighborhood up step by step. If the cabin is obtainable, delivery the engine and set the defroster on low-to-medium with blended air, now not full scorching blasting the cold glass. Inside warm makes the inner layer escalate, which can arch the laminate and coax a crack. Gradual is the watchword.

Contamination handle is harder inside the cold. If the chip has moisture, you will have to dry it, yet you can't shock the glass. I will cycle heat lightly, enable it relax, then vacuum with the injector to pull vapor. Watch for fog clearing throughout the legs. If you see tiny bubbles rising, you’re at the good tune. Patience issues extra than tools right here.

Resin collection shifts in winter. Use a curb viscosity resin to make amends for the bloodless, regularly in the 15 to 25 cP fluctuate for injection, and a barely thicker pit resin for capping. Keep resin bottles in an internal pocket or a hot case. Cold resin turns syrupy and traps microbubbles that won’t upward thrust.

Vacuum and rigidity cycles need more time. In a heated bay, I might do two cycles of 60 to ninety seconds each one. In the cold, I’ll double that. The objective is to use time to exchange brute power. If the chip nevertheless shows ghost legs after drive, go into reverse, heat rather once again, and repeat. Aggression breaks glass in wintry weather.

UV cure speed slows down in cold, even in direct sun. If you’re using a lamp, understand its output in milliwatts per rectangular centimeter and flow it in close, however shop the warmed glass reliable. Typical discipline lamps need 2 to five mins in most fulfilling circumstances. In the chilly, deliver it 5 to ten mins, then a secondary cure after scraping the pit fill. Test with a probe. If the pit resin gums your blade, it demands greater UV.

I as soon as watched a technician faucet too onerous when probing a celebrity leg at 25 F. The leg ran two inches in a heartbeat. If you test, do it at the cease, and simplest when you belif the fill has penetrated. Gentle finger power at the inner can screen voids, yet be careful with defroster strains. Any brought localized warm will become a multiplier within the cold.

Hot climate: above 90 F, you’re racing the clock

Heat flips the main issue. Resin gets runny, running time evaporates, and the glass expands, which briefly narrows some microcracks. You can inject, imagine you stuffed it, then watch as a cooler nighttime unearths voids simply because the legs reopened because the glass shriveled. The repair is to manipulate temperature and timing so your fill remains suitable as soon as the glass normalizes.

Shade isn't non-obligatory. Create it if you needs to. A reflective windshield conceal and a canopy will lower floor temps by 10 to twenty levels. Measure the glass. If it’s over one hundred F, do not inject but. Bring it all the way down to the 70 to ninety range with colour, airflow, and endurance. Avoid open water misting, which may push moisture into the damage. If you need evaporative cooling, very easy mist clear of the chip, paired with a fan, can help slowly drop temp, however not at all shock the glass.

Resin range in the heat leans thicker, 30 to 60 cP for the major injection, since thin resin can flood, run, and underperform in shear. Some techs pick a medium viscosity in spite of weather, yet on a 105 F deck, increased viscosity buys manipulate.

Work rapid, yet not rushed. Pre-degree everything. Impact point wiped clean and burred basically if obligatory. Bridge assembled and aligned beforehand you open resin. In top warm, a commonly used UV lamp can treatment a skinny film in seconds. Accidental remedy occurs if you happen to face the chip towards direct sunlight at the same time as you fumble a seal. Keep a UV protect over the region until eventually you’re capable.

Pressure turns into problematical. Excess stress on extended glass can coax a leg to go. Use scale back pressures and more cycles. Monitor with a mirror from the interior if you'll. If the chip seems to be to fade under force however ghosts occur whenever you unlock, the legs are respiratory with temperature. That’s a signal the glass continues to be too hot or your viscosity is just too low. Cool it a bit of greater, then try out back.

Curing in warm can cause floor cure with an undercured core if you happen to blast it too quickly. I decide upon a staged healing: a short tack medication for 20 to 30 seconds to fasten the fill, a minute leisure, then a full treatment cycle for various mins. After scraping and pit filling, give a generous ultimate therapy. In high UV environments, circumvent cooking the laminate. The trick is consistent, managed energy, no longer a weld in one shot.

Finally, watch out for thermal shock if the patron drives off and cranks the AC to complete chilly pointed at a one hundred fifty F windshield you simply worked on. Recommend a sluggish cool-down. I additionally warn towards automated vehicle washes all of the sudden after a scorching-day restore. Sudden bloodless water on a still-heat panel is the incorrect type of attempt.

The cell chip fix reality

Mobile chip fix is a varied animal. You don’t usually get a garage, and you can actually’t choose your climate. You can still stack the deck. I save an insulated case for resins, a compact canopy, a low-temp warm gun, a fan, a UV blocking off drape, a tumbler thermometer, and two bridge setups so I can transfer if a seal acts up. The element is to govern a small bubble of surroundings around the chip. In iciness, the warm case and a chargeable pad less than the resin bottle make all of the big difference. In summer, the cover and a UV maintain prevent from unintentional flash remedies.

There’s also the logistics of parking. In the chilly, I set the auto nostril far from the wind, door cracked on the edge I’m working, and the local weather set to a slight hot combination to gently back-hot the glass. In the heat, I seek pure color aligned so the restore spot avoids direct glare in the course of the definitely injection and therapy. Customers discover that point of care, but greater importantly, it avoids do-overs.

When to repair and while to pass

Not each chip is an efficient candidate in serious climate, exceptionally on the facet of the street. Here are the crimson flags that push me toward replacement or a managed save ecosystem:

- A famous person smash with a standard leg inside an inch of the brink. The part is a tension riser. Temperature will make the most it. Moisture intrusion you will not confidently dry, incredibly if the chip sat as a result of a freeze-thaw cycle. White haze in the damage is a tell. Long cracks already reward beyond 6 to 8 inches, or any crack originating from a chip that differences appreciably in the event you observe gentle finger rigidity inside the cold or warmth. Multiple close-proximity chips within the driver’s field. Even if you are able to fill them, the optical footprint and structural integrity business-offs develop. Laminated glass with aftermarket tint films utilized internal near the hurt. Heat during therapy can ripple the film.

You can still participate in windshield crack restore if the crack is brief and solid, but excessive temperatures scale back your luck odds. Better to carry the automobile into a controlled bay or advise for substitute if defense is in query.

Real-international eventualities that structure judgment

A fleet van on a January morning, chip lifeless center, big name legs faint but visual. Outside temperature at 14 F, glass at 17 F. I warmed from within first with a low defrost surroundings, 5 mins, then used a heat gun outside sweeping circles, in no way preventing close the effect. Brought the surface to 68 F. Vacuumed for three minutes, tension for 3, repeated twice. The legs took resin slowly yet completely. Cure took 8 minutes with a high-output lamp. The tech subsequent to me rushed and cured in three minutes. His pit looked glossy, yet by using afternoon that van had a faint haze wherein the middle hadn’t solely set. Mine held sparkling.

Another case: black sedan in August, parked on asphalt, hood and glass roasting. Surface temperature at the chip measured 129 F. I refused to inject unless I got it beneath ninety. Canopy up, reflective conceal on the sprint, doors open, fan running. It took 20 minutes. Used a medium-high viscosity resin, low strain, repeated cycles. Staged treatment to steer clear of floor lock. A week later the visitor suggested no ghosting at nightfall, which is frequently whilst scorching-day maintenance tutor their flaws.

Judgment feels like this: your time up front stabilizing temperature is just not wasted. It’s the maximum effective element of the task.

Tools and parts that pay for themselves

Good auto glass restoration in severe climates favors a short listing of solid equipment. I worth an infrared thermometer over any fancy app. I rely upon a bridge with a rigid physique and precise stress handle. I bring each low and medium viscosity resins from respectable manufacturers, saved in UV-blockading bottles. A UV lamp with widely used output, ideally at least 365 nm with 20 to 50 mW/cm² on the operating distance, beats guessing lower than cloud conceal.

Consumables trade faster in warm and cold. Seals stiffen in wintry weather and soften in summer. Replace them more almost always otherwise you’ll combat leaks or inconsistent suction. Keep extra pit tape, and don’t skimp. In the cold, adhesive fails quicker. Clean the sector with a non-ammonia glass cleanser and permit it flash off solely. Ammonia can linger and mess with resin bonding.

If you do telephone chip restore incessantly, a compact battery energy station lends independence for lighting fixtures, enthusiasts, and warmers. Control is the subject from birth to finish. The more variables you tame, the more desirable the repair.

Small procedure modifications that matter

Impact aspect clearing may still be minimal. In the chilly, drilling aggressively invitations a run. Use a tiny burr at low speed to get rid of overwhelmed glass solely, then prevent. In warm, the glass can smear at the sides of the have an effect on, so save your bit sharp and your rigidity faded. I ceaselessly bypass drilling if the effect is open sufficient to accept resin under vacuum.

Injectors improvement from a little reduce angles in critical stipulations. A flatter mindset reduces lateral strain. If you tilt an excessive amount of, the seal deforms inconsistently and you get wasteful resin creep. Keep your bridge ft blank. On sizzling glass, rubber toes can scuff or stick, which differences your load at the crack legs as you adjust.

Watch your cues. In bloodless, bubbles transfer sluggishly and by and large reside pinned except you elevate rigidity. If they don’t budge after several cycles, upload a easy warming cross, then repeat vacuum. In warmth, microbubbles rise quick but can coalesce on the effect level. Burp the injector carefully to launch trapped air devoid of exposing the resin to direct solar.

Scraping is its very own possibility in the bloodless. A stiff blade on chilly glass can score or chatter. Warm the surface a slightly and dangle the blade shallow. In warm, resin airborne dirt and dust will get tacky. Keep the blade refreshing, pull smooth, and restrict digging the pit.

Customer practise maintains upkeep from failing

Most drivers don’t be aware why a coin-sized chip wishes distinct handling on a freezing or blistering day. A instant, positive explanation prevents moment-guessing and protects the restore. I recurrently prevent it simple.

First, I provide an explanation for that temperature makes glass broaden or contract, which opens or closes the wonderful cracks radiating from the chip. Second, I define what I’m doing to stabilize the sector and why we need several excess minutes. When the task’s achieved, mobile auto glass Belmont I give two requests: dodge dramatic temperature swings for a better a few hours, and don’t hit a auto wash that day. That’s it. People remember ordinary, and your fix gets a reasonable threat to set.

If a shop treated your remaining fix and it failed inside of days throughout the time of a heatwave or cold snap, that doesn’t automatically mean negative workmanship. It may also suggest the glass moved greater than anticipated, or the break turned into extra extreme than the surface recommended. Still, a pro technician will assume these stresses and regulate.

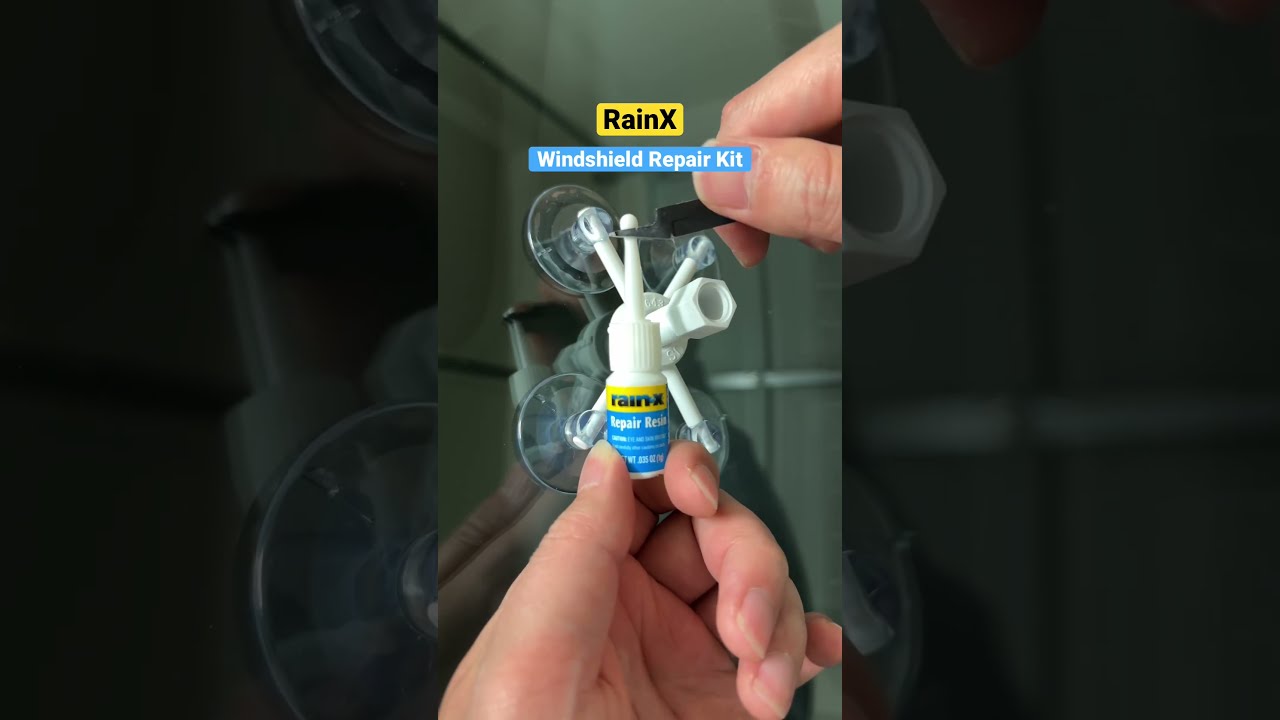

DIY kits in serious weather: straightforward expectations

There’s a spot for DIY. If you’re careful and the chip is simple, you could possibly stabilize it. In harsh temperatures, the percentages slip until you handle conditions. Kits hardly incorporate temperature instruction beyond a imprecise “room temperature.” If you don’t have a shaded house and some way to heat or cool the glass gently, wait till you do. Avoid driveway upkeep at midday in July or at first light in January.

If you check out it anyway, prioritize cleanliness, soft warmness within the cold, colour in the warmth, and slow force ameliorations. If you spot the legs flow, stop. You’re with regards to a run. That’s the instant to contain a pro.

The restore-versus-replace economics shift with weather

A generic rock chip restoration is instant and rate-effective, recurrently included through assurance and not using a deductible. In serious situations, time extends. Mobile chip repair in winter or summer time heat can take 30 to 60 minutes instead of 15. That’s nonetheless a bargain compared to substitute, surprisingly on autos with rain sensors, heated glass, or ADAS cameras that require recalibration. But if the break sits too with regards to the threshold or has grown into an extended crack, you’re risking more time and a minimize achievement charge. That’s when windshield alternative turns into the liable name.

Longevity subjects. A neatly-carried out fix in strong temperatures can nicely halt spread for the existence of the windshield. In serious-weather upkeep, fulfillment remains to be elementary, but the opportunity of faint ghosting or moderate optical distortion goes up. Be transparent approximately that. Most valued clientele desire a small, faint mark over a full replacement and a day misplaced to calibration.

A compact discipline list for intense temperatures

- Measure glass temperature on the restore site, no longer just ambient air. Target 60 to 90 F earlier injection. Control the surroundings with colour, gentle warm, or airflow. Avoid quick variations. Match resin viscosity to circumstances. Thinner in cold, thicker in warm. Use longer vacuum and rigidity cycles with lessen strength. Let time do the heavy lifting. Stage the UV healing to stay away from surface lock and ensure middle set, fairly in heat or chilly.

Final feelings from the field

The wonderful maintenance I’ve considered in brutal temperatures came from techs who treated the glass with staying power and care, now not bravado. They adjusted resin, they managed temperature, they resisted the urge to pressure a quick healing. They also knew while to claim no. Windshield crack restore has limits, and serious climate exposes them.

Rock chip restore is a craft. On gentle days, the craft hides in the back of a quick influence. On harsh days, it indicates. Control the variables, recognize the glass, and take the excess mins to do it good. Whether you’re wrenching in a windblown lot or working beneath a blazing sun, the difference among a fail and a clear shop is hardly luck. It’s judgment, equipped one cautious restore at a time.